Services

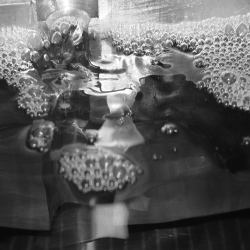

VPD is equipped with the latest Mold Design and CNC Machining Technologies to support the design and build of injection molds for small intricate parts as well as large part mold tooling up to 3 tons. Utilization of 4 axis machining capabilities and machining travels up to 30” x 74” x 40” VPD can manage complex geometries and large part surfaces with precision. With more than 10 CNC machines surrounded by specialized mold-making support equipment working in harmony with our expert staff in our modern plant - you can be sure that your next project will be of high quality and delivered on schedule.

VPD's quick turnaround - lower cost - High Performance Aluminum Molds are an all American tooling solution for prototype to production applications, and will out perform conventional molds by reducing delivery schedules and overall molded part costs while increasing your profits.

Have a new idea or invention? Let us help you make that new invention idea become a reality. Need special parts machined? Our skills in design and manufacturing of complex molds make us the ideal choice for those one off, special rare machine or custom parts in all types of materials. Have a problem mold? Let our expert mold makers repair that tool quickly and get you back in production. When time, cost and quality are important - you have a new option - Venus Product Development. Your source for product design, machined prototypes, prototype aluminum injection molds, production injection molds, investment cast dies, die cast tooling, compression and forming tools, expert mold repair, CNC machining, and custom machining for one part or many. Contact us today to discuss your project or for more information about VPD.